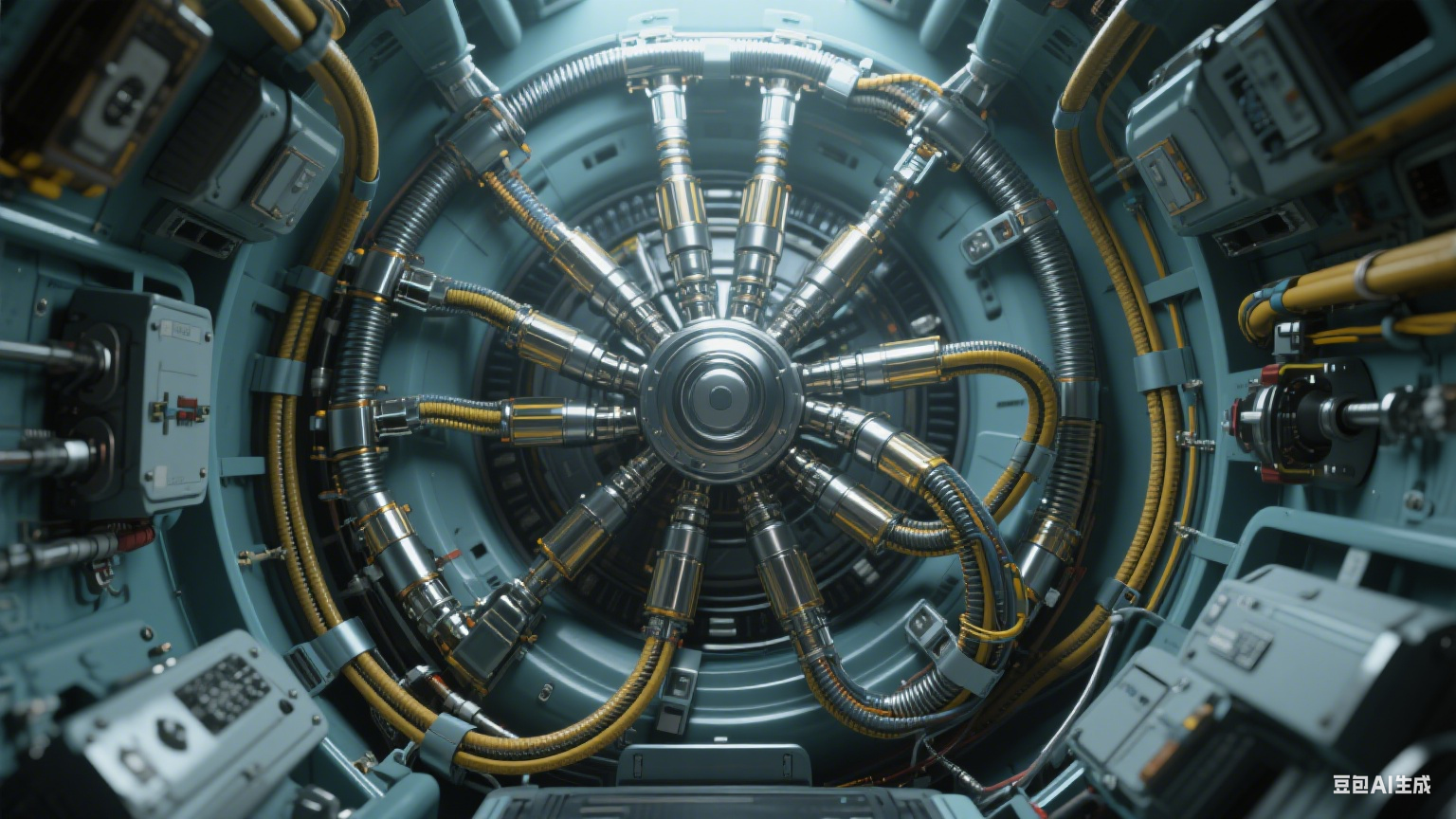

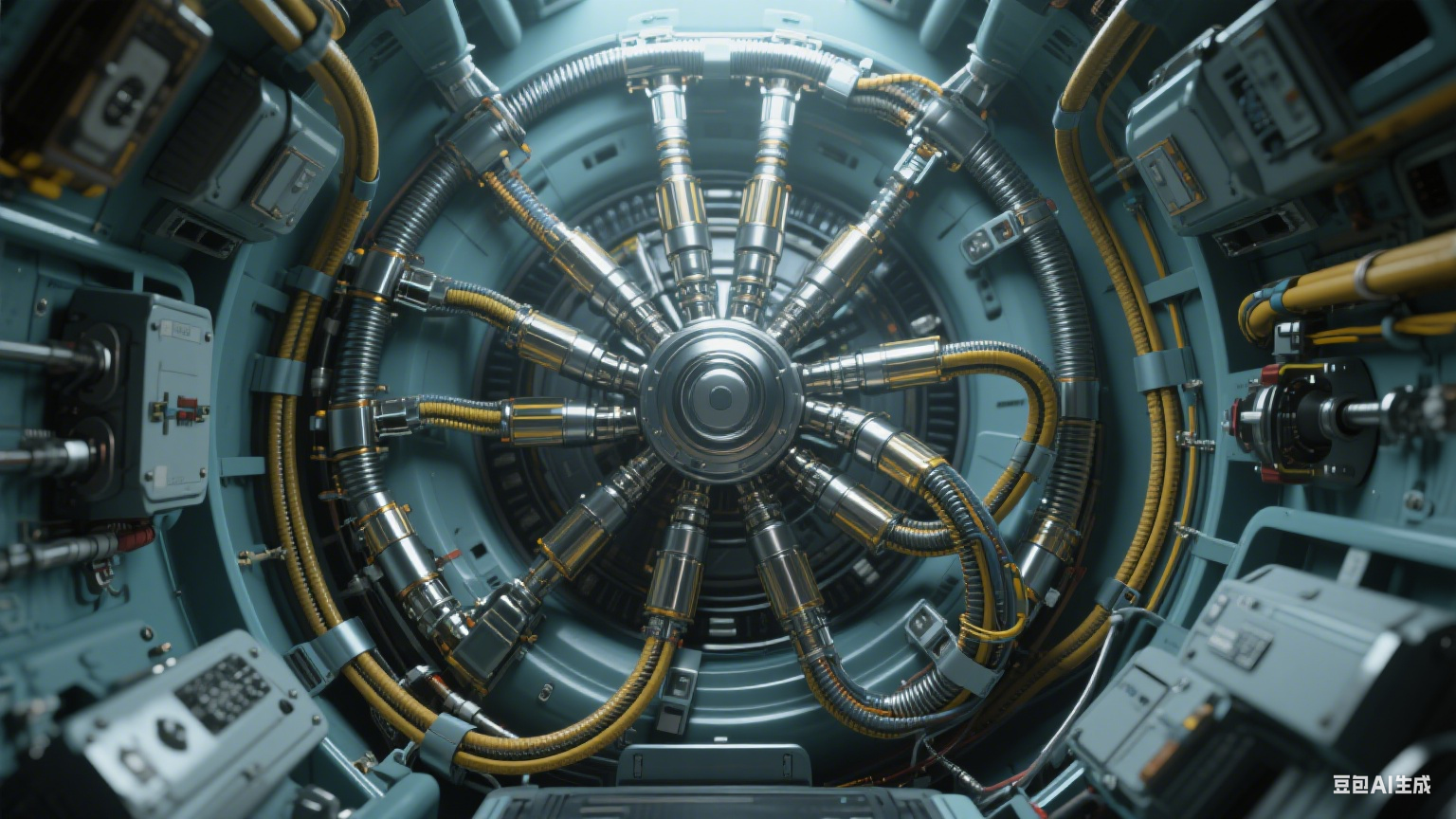

New Innovations in Aircraft Cable Assemblies Enhance Flight Safety

In the aviation industry, where even the smallest component can have a profound impact on safety, aircraft cable assemblies play a critical role. These assemblies are the lifelines that connect various systems, ensuring seamless communication, power transmission, and control operations. With the constant pursuit of safer and more reliable flights, recent innovations in aircraft cable assemblies have brought about significant advancements, greatly enhancing flight safety.

Advanced Materials for Enhanced Durability

One of the key innovations in aircraft cable assemblies is the use of advanced materials. Traditional cables often struggle with issues such as corrosion, fatigue, and high-temperature resistance. However, new materials like high-strength titanium alloys and carbon fiber composites are changing the game.

Titanium alloys offer exceptional strength-to-weight ratios, making them ideal for reducing the overall weight of the aircraft without compromising on durability. They are highly resistant to corrosion, even in the harsh environments encountered at high altitudes and during flights over oceans. Carbon fiber composites, on the other hand, provide superior tensile strength and can withstand extreme temperatures, ensuring that the cables remain functional in the demanding conditions of engine compartments and other high-heat areas.

These advanced materials significantly extend the lifespan of aircraft cable assemblies, reducing the frequency of replacements and minimizing the risk of unexpected failures during flight.

Improved Design for Optimal Performance

In addition to material advancements, the design of aircraft cable assemblies has also seen remarkable innovations. Engineers are now focusing on creating more streamlined and efficient designs that reduce friction, improve flexibility, and enhance overall performance.

One notable design improvement is the implementation of multi-strand configurations. By using multiple smaller strands instead of a single large one, the cables become more flexible, allowing for easier installation in tight spaces and reducing the stress on the cables during movement. This flexibility also helps to minimize fatigue, as the cables can better absorb the vibrations and shocks experienced during flight.

Another design innovation is the integration of protective sheaths made from high-performance polymers. These sheaths provide an extra layer of protection against abrasion, moisture, and chemical exposure, further enhancing the durability and reliability of the cable assemblies.

Smart Monitoring for Proactive Maintenance

Perhaps one of the most groundbreaking innovations in aircraft cable assemblies is the integration of smart monitoring technologies. These technologies allow for real-time monitoring of the cable’s condition, enabling proactive maintenance and early detection of potential issues.

Sensors embedded within the cable assemblies can measure various parameters such as temperature, strain, and resistance. The data collected by these sensors is transmitted to a central monitoring system, where it is analyzed by advanced algorithms. This allows maintenance crews to identify any signs of degradation or damage before they lead to a failure.

For example, if a sensor detects an increase in resistance in a particular section of the cable, it could indicate a potential break or corrosion. Maintenance teams can then take immediate action to repair or replace the affected cable, preventing a possible in-flight malfunction.

Case Study: Reducing Failures with Innovative Cable Assemblies

A leading airline recently upgraded its fleet with the latest aircraft cable assemblies incorporating these innovations. Over a six-month period, the airline reported a 35% reduction in cable-related failures compared to the previous period. This not only resulted in fewer flight disruptions but also significantly improved the overall safety record of the fleet.

The maintenance team noted that the advanced materials and improved design made the cables much easier to inspect and maintain, while the smart monitoring system allowed them to address potential issues before they became critical.

Compliance with Strict Industry Standards

All these innovations in aircraft cable assemblies are developed and tested in strict compliance with the rigorous standards set by aviation regulatory bodies such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA). This ensures that the new cable assemblies meet the highest safety requirements and can be reliably used in commercial and military aircraft.

Manufacturers conduct extensive testing, including vibration testing, temperature cycling, and corrosion resistance testing, to validate the performance and durability of the innovative cable assemblies. Only after passing these stringent tests are the products approved for use in aircraft.

In conclusion, the new innovations in aircraft cable assemblies, from advanced materials and improved designs to smart monitoring technologies, are revolutionizing the aviation industry. These advancements are not only enhancing the durability and performance of cable assemblies but, more importantly, are significantly improving flight safety. As technology continues to evolve, we can expect even more innovative solutions in the field of aircraft cable assemblies, further ensuring the safety of passengers and crew around the world.

**