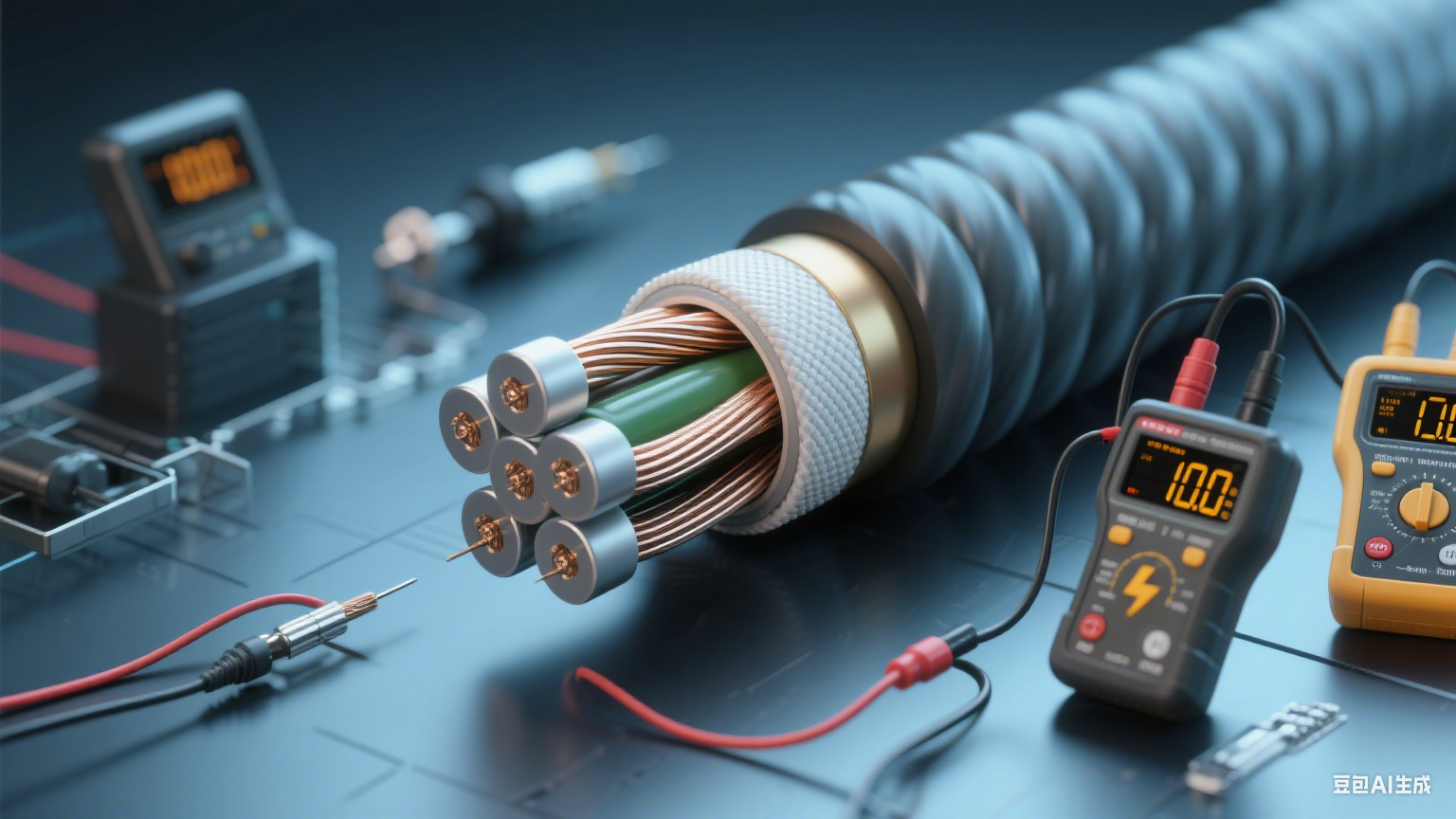

How to test aviation cable assemblies for reliability?

Aviation cable assemblies are vital components in aircraft, responsible for transmitting electrical signals and power. Their reliability directly affects the safety and normal operation of the aircraft. Therefore, conducting comprehensive and rigorous reliability tests on aviation cable assemblies is of great significance. The following will detail the specific methods for testing the reliability of aviation cable assemblies.

Electrical Performance Testing

Electrical performance is a key indicator of aviation cable assemblies. Insulation resistance testing is an important part. Use an insulation resistance tester, connect one end of the tester to the conductor of the cable assembly and the other end to the insulation layer. Apply a specified DC voltage (usually 500V or 1000V) for a certain period (generally 1 minute). The insulation resistance value should meet the relevant standards. If the value is too low, it indicates that the insulation layer is damaged or damp, which may cause leakage or short circuit.

Conductivity testing is also essential. Use a multimeter or a dedicated conductor resistance tester to measure the resistance of the cable conductor. The resistance value should be within the specified range. Excessive resistance may lead to excessive heat generation during current transmission, affecting the normal operation of the equipment.

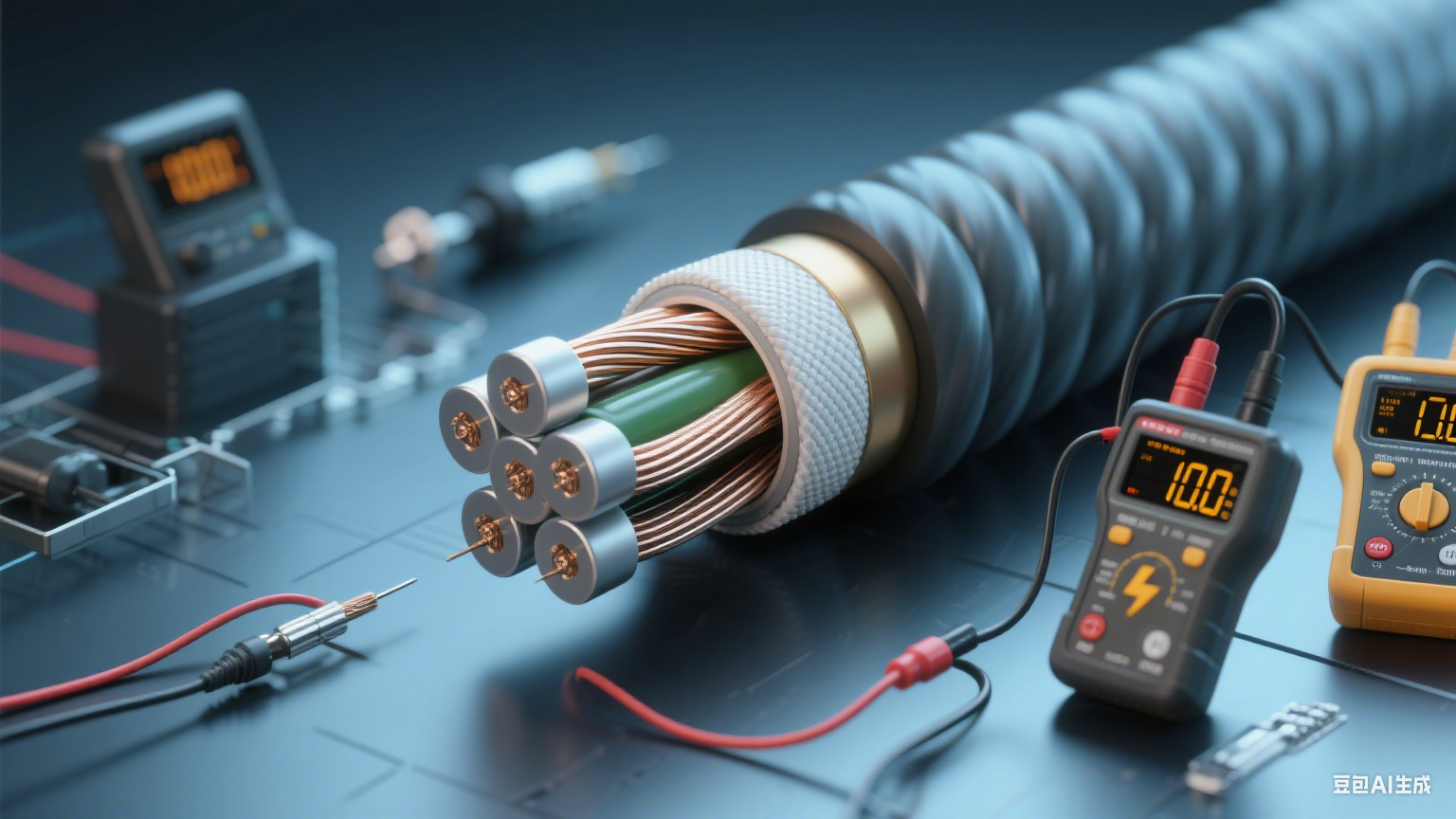

耐电压测试(Withstand voltage test)is to check the ability of the cable assembly to withstand high voltage without breakdown. Apply a higher AC or DC voltage than the working voltage between the conductor and the insulation layer (or between different conductors) for a certain time (such as 1 minute). If there is no breakdown or flashover, the test is qualified. This test can effectively detect hidden dangers such as insulation defects and weak points.

**

Mechanical Performance Testing

Mechanical performance tests ensure that aviation cable assemblies can withstand various mechanical stresses during installation and use. Bending test is one of them. Fix one end of the cable assembly, and bend the other end at a specified angle (such as 90 degrees or 180 degrees) for a certain number of cycles (like 1000 times). After the test, check whether the cable’s structure is damaged, such as cracks in the insulation layer or broken conductors. If the cable fails this test, it may not be able to withstand the bending during installation and use, leading to performance degradation or even failure.

Tensile test: Clamp both ends of the cable assembly on a tensile testing machine, apply a specified tensile force at a certain speed, and maintain it for a period of time. After the test, check if the cable has obvious elongation, conductor breakage, or insulation layer peeling. The tensile strength should meet the design requirements to ensure that the cable will not be pulled apart during installation or use.

Vibration test: Install the cable assembly on a vibration test bench, simulate the vibration environment during the flight of the aircraft, set the vibration frequency, amplitude, and duration according to the relevant standards. After the test, check the electrical performance and mechanical structure of the cable assembly. If there is a significant change in electrical performance or structural damage, it indicates that the cable assembly is not suitable for the vibration environment.

**Environmental Testing

Aviation cable assemblies work in harsh environments, so environmental testing is crucial. High and low temperature test: Place the cable assembly in a high and low temperature test chamber. Set the high temperature (such as 125°C) and low temperature (such as -55°C) values, and keep each temperature for a certain time (like 24 hours). After the test, take out the cable assembly and let it return to room temperature, then test its electrical and mechanical properties. This test can check the stability of the cable assembly under extreme temperature conditions. If the performance changes significantly, it cannot meet the use requirements.

Humidity test: Put the cable assembly in a constant temperature and humidity chamber, set the temperature (such as 40°C) and relative humidity (such as 90% – 95%), and maintain it for a certain period (like 10 days). After the test, check the insulation resistance and other electrical properties. Excessive humidity may cause the insulation performance to decline, affecting the reliability of the cable assembly.

Salt spray test: This test is mainly for aviation cable assemblies used in coastal or high-salt environments. Place the cable assembly in a salt spray test chamber, spray a salt solution (usually 5% sodium chloride solution) with a certain concentration, and maintain it for a specified time (such as 48 hours). After the test, check the surface corrosion of the cable assembly and the changes in electrical and mechanical properties. Corrosion may lead to poor contact or structural damage of the cable assembly.

**

When it comes to ensuring the reliability of aviation cable assemblies, FRS brand factory is your trusted partner. With advanced testing equipment and professional technical teams, FRS conducts all the above-mentioned tests strictly to ensure that each aviation cable assembly meets the highest standards of reliability. Choose FRS, and you can be confident in the performance and safety of your aviation cable assemblies.