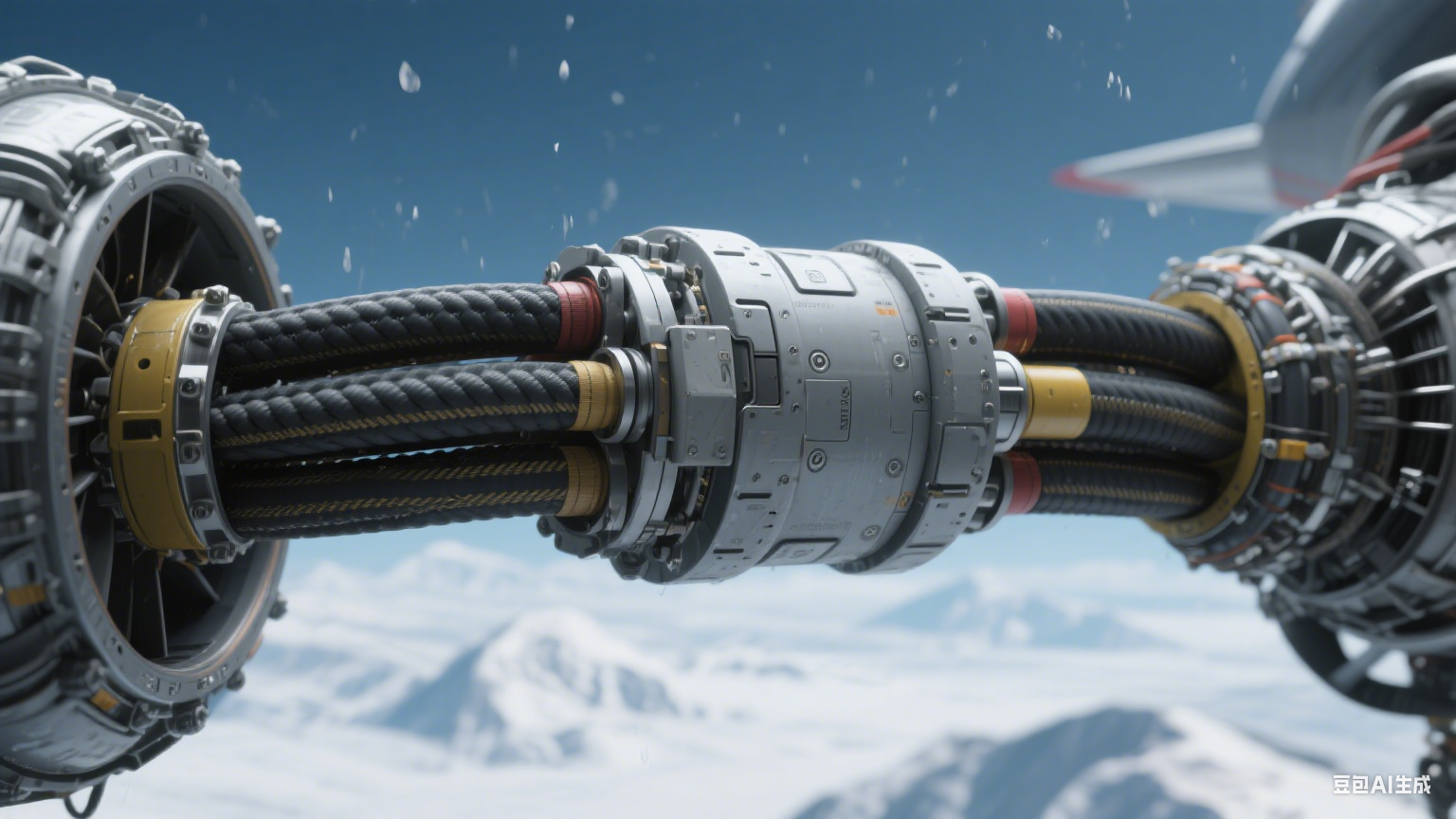

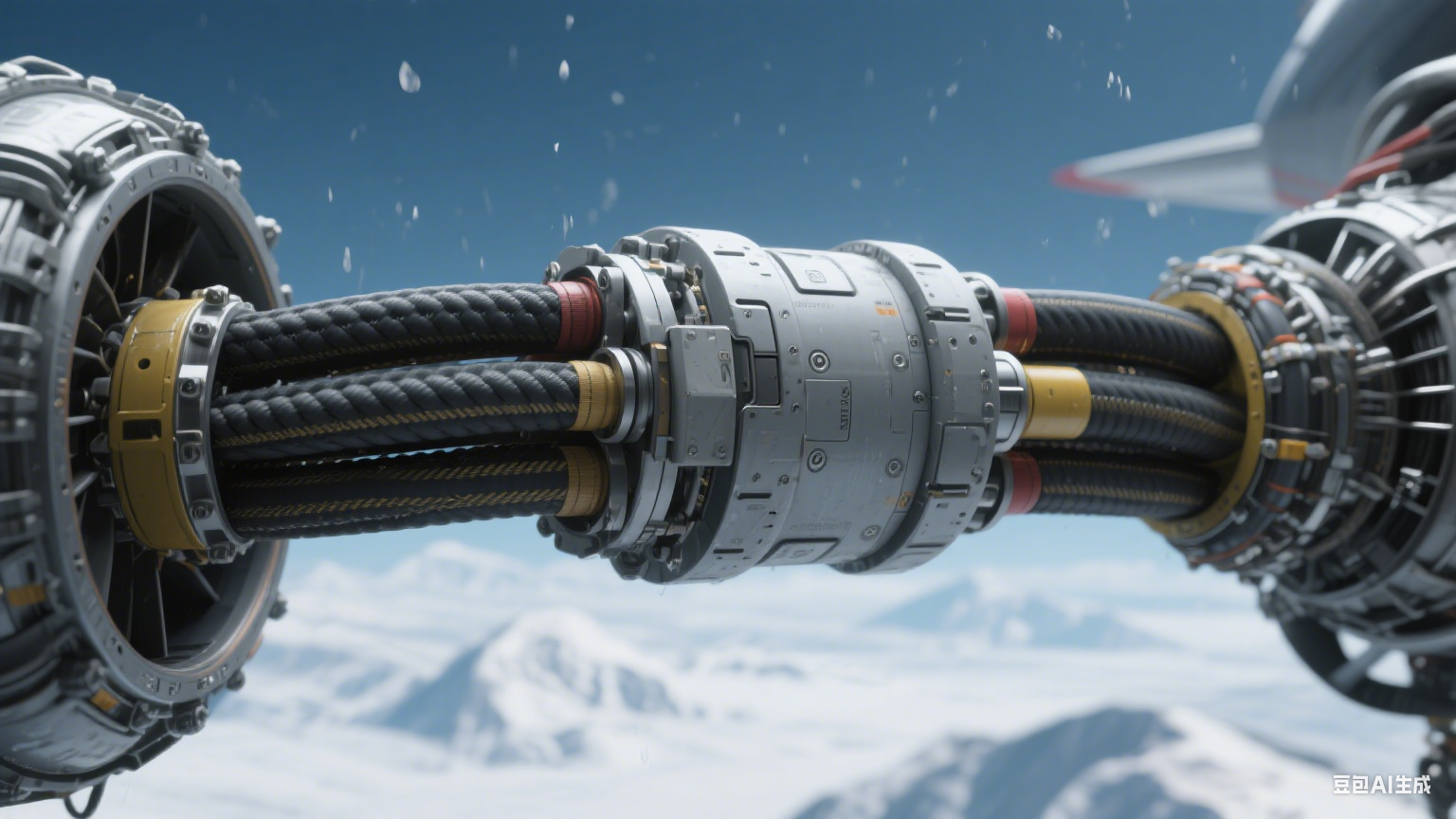

How Aircraft Cable Assemblies Improve Aircraft Performance

Aircraft cable assemblies are the unsung heroes of aviation, serving as the vital nervous system that connects and powers critical systems. Beyond mere connectivity, these precision-engineered components play a pivotal role in enhancing aircraft performance across multiple dimensions, from efficiency to safety.

Ensuring Uninterrupted Signal Transmission

In the complex network of an aircraft’s avionics, communication between systems is non-negotiable. High-quality aircraft cable assemblies are designed to minimize signal loss and interference, even in the harsh electromagnetic environment of a flying machine. This ensures that data from sensors, navigation systems, and flight controls is transmitted accurately and in real-time. For example, in autopilot systems, a split-second delay or a corrupted signal could lead to incorrect adjustments, but reliable cable assemblies prevent such issues, allowing for precise and smooth flight operations.

**

Reducing Weight for Enhanced Efficiency

Weight is a critical factor in aircraft performance, directly impacting fuel consumption and payload capacity. Modern aircraft cable assemblies are crafted using lightweight materials such as high-strength alloys and advanced polymers, without compromising on durability. By reducing the overall weight of the aircraft’s wiring harness, these assemblies contribute to lower fuel usage, extended range, and increased operational efficiency. For commercial airlines, this translates to significant cost savings over time, while for military aircraft, it means improved maneuverability and mission capabilities.

Withstanding Extreme Conditions

Aircraft operate in a wide range of extreme conditions, from freezing temperatures at high altitudes to the heat generated by engines. Aircraft cable assemblies are built to withstand these harsh environments. They are resistant to temperature fluctuations, vibration, moisture, and chemical exposure, ensuring consistent performance throughout the aircraft’s lifespan. This durability reduces the risk of system failures due to cable degradation, enhancing the overall reliability and safety of the aircraft.

**

Enhancing Maintenance Efficiency

Well-designed aircraft cable assemblies are not only reliable but also easy to maintain. They are often color-coded and labeled, making it simple for maintenance crews to identify and access specific cables during inspections or repairs. Additionally, their robust construction minimizes the need for frequent replacements, reducing downtime and maintenance costs. This allows aircraft to spend more time in the air and less time on the ground, improving operational availability.

When it comes to reliable and high-performance aircraft cable assemblies, FRS brand factory stands out. With years of experience in the aviation industry, FRS is committed to producing top-quality cable assemblies that meet the strictest standards. Using advanced manufacturing techniques and premium materials, FRS ensures that each product delivers exceptional performance, durability, and efficiency. Choose FRS for your aircraft cable assembly needs and experience the difference in aircraft performance.